by David Davenport | Oct 14, 2021 | References

We are proud to announce we are going to present our IONA System at Robotics & Automation 2021, 2&3 November, in Coventry. Our flagship product IONA has been developed to tackle the challenges of robot performance and flexibility. The hardware and software...

by David Davenport | Oct 5, 2021 | References

Digital Twin Digital Twin – The Challenge Creating a digital replica of a manufacturing process (often referred to as a digital twin) allows changes to be assessed, programmed and validated offline before needing to change the physical system. This can be...

by David Davenport | Oct 5, 2021 | References

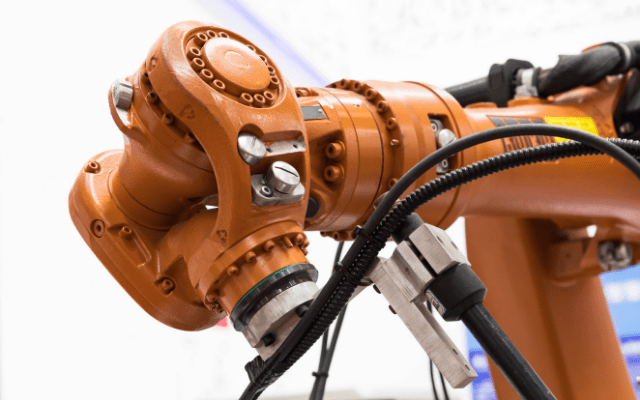

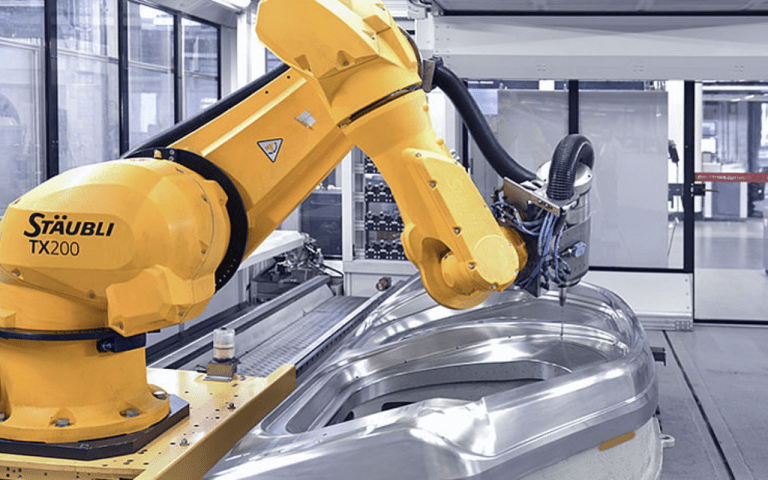

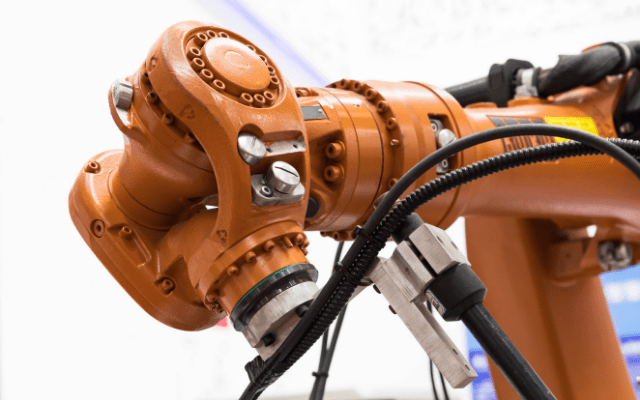

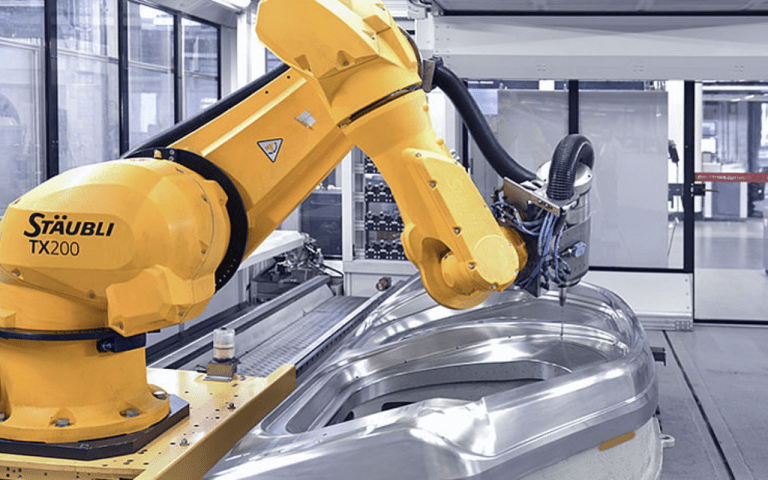

Robot Machining with IONA by INSPHERE The Challenge Robots typically rely on their repeatability to perform automated operations but there are some tasks where inherent accuracy is just as important. One example of this is robot machining operations, particularly so...

by David Davenport | Oct 5, 2021 | References

The Challenge When a robot fails in production, unplanned downtime can cost over £10,000 per minute in high throughput systems. As mechanical systems, robots are also subject to wear and tear and their positional accurate can ‘drift’ over time. This can result in...

by David Davenport | Oct 5, 2021 | References

The Challenge Typically, robots rely on their repeatability not their accuracy. When a robot first moves to a programmed position it may only get there to within +/- 2mm. It will however always go back to that same position to within +/-0.05mm. This lack of accuracy...

Recent Comments