WHAT IS ARK FLASH INFO

Ark Flash Info is a site that is packed with Information…Solutions… Superb Companies with… Leading-Edge Related Products, but most of all it is your tool..that will answer all your questions.

Advice on Outages and Isolation Procedures: Just request on enquiry or via chat for no-cost advice and guidance.

ProGARM

Arc Flash PPE

Remote Switching

Energy Audits

Retro-Fit HV & LV Arc-Flash

Detection and Protection Panels

Form 4 Switchgear & Panel Builds

ARCTEQ

Arc Flash Relays

Quenchers and Protection IEDs

SKANWEAR

Saving Lives

Reliable safe solutions

Ark Flash Info support line +44(0)1922 402343 EET 9:00 – 17:00

10 TYPICAL CAUSES OF ARC FLASH

Carelessness

- ‘Human error

- Incorrect AF PPE, (There should be clear signage dictating category level) IF in doubt ask for advice via enquiry form, email or chat.

- Poor organising of isolations and lock out procedures

- Electrical engineers not trained to SAP level

- Tools not rigorously checked in and checked out to ensure none left behind after any works

- No safety representative (should be present at all times) with the SAP working or switching to isolate. Call or complete enquiry form for more information and/or advice.

- Failure to ‘CONFIRM DEAD’ via SAP/ Authorised Engineer

- Failure to ‘PROVE DEAD’ via SAP/Authorised Engineer

- Overlooking a completed and signed work permit with

- Full switching statement

- RAMS

- Preferably dynamic Risk Assessment, (to be completed by attending engineer as situations change, new dangers may appear that is not obvious to the author of SS or RAMS)

Remember, PPE is the ONLY item on here you can make full proof and is YOUR own decision-making process. For more information, guidance and advice on any or all of the above complete enquiry form or seek chat assistance.

Worn or broken conductor or busbar insulation

The condition of cabling, glands, terminations and busbars are usually quite evident, visually inspect, if possible, check torque levels and/or use a thermal image tool to give a really good indication of condition or possible loose connections.

The switchgear panels and arrangements are not always accessible, so utilise the time wisely and pro-actively.

Note findings, report and follow up. Reputations and confidence are duly enhanced by good housekeeping habits. Call or complete enquiry form for advice.

NB.Professional thermal imaging reports are known to pay for themselves in saving potential breakdown and AF situations.

Exposed live parts

You may think they are dead, but always worth checking. Whether dead or live:-

- Working ABOVE an exposed busbar run

- Ensure all is fully covered and sealed off prior to any works

- Working at the SIDE of an exposed busbar run

- Ensure all is fully covered and sealed off prior to any works

- Working BELOW an exposed busbar run

- Ensure all is fully covered and sealed off prior to any works

A dropped tool can be an end of life and/or an end of facility supply for a sustained period

Loose wire connections

Regular Thermal imaging reports are possibly the best investment a company can provide for PPM and preventing issues before they arise. If a company has an exceptionally tight budget, this should be the first essential, behind correct category PPE. A small investment for a complete picture of condition of operating switchgear and any suspect areas that require attention. An overlooked connection that has worn loose can cost lives, injury, repair/replacement cost and lost- production

Improperly maintained switches and circuit breakers

An OEM will always give recommended service periods, (usually 12 monthly). Sometimes overlooked by Chief Engineers or Engineering Managers, (then when there is an issue, the fingers are pointed??). Call or complete enquiry form for more information.

Faulty connections, mechanical interlocks or triggering systems can lead to dangerous situations.

Incorrect switching/isolations/Switching statements

It happens more frequently then most would expect, additions to original switchgear, schematic/SLD’s not updated, incorrect or missing ident labels, inexperience engineer, new sites, switching via communicated instructions. IF IN DOUBT… DO NOT.. Call or complete enquiry form, request chat, (8am-6pm Mon-Fri) for more information.

Water, liquid, condensation, damp near electrical equipment

Buildings deteriorate, roof and window leaks, , condensation, fans with damaged or even no mesh, doors unevenly hung, rodents, dust, debris, cluttered floor, rusted or paint chipped frameworks. A substation and/or switchroom should be kept in good clean condition, it will benefit the control and switchgear and remove many of the pending hazards.

Tools dropped or left upon High OR Low voltage cables or busbars

Good practice is to count in and count out all tools, seal off exposed or accessible busbars and sections with cable terminations whenever possible. If you are responsible for TOOL BOX TALKS, reinforce this to all engineers

Static electricity

A small spark is all it needs to generate an arc between two phases or phase to earth, then the domino effect but……. with an arc that can be 4 times hotter than the surface of the sun.

The right PPE, non-static underwear, rubber insulation mats in place, clean and painted floor-ways and work/operation areas. If it is missing…report it as a NEAR MISS, any good company will thank you for your professionalism

Damaged tools and equipment

A worn spanner can slip!! A spanner or ANY tool without HV insulation should not even be a consideration. Keep all tools clean and grease free, maintain a tidy work station/tool box. Replace damaged and worn tools. COUNT IN…AND …..COUNT OUT on every work situation! Include in your Method Statement to ensure good practice is consistantly reminded.

ProGARM

Arc Flash PPE

PPE providers that sponsor our site are experts in this field and can provide the exact requirements and any advice and guidelines. Please either deal direct, https://progarm.com/ or if you wish us to oversee at no additional cost to project or budget, either email david.davenport@transmaguk.co.uk or fill out our website enquiry form here.

10 typical SubStation / Switchroom tell-tale situations to be mindful of

Damaged buildings

Roofs that leak; Fan with damaged or no mesh; broken windows, uneven hung/badly fitting doors.

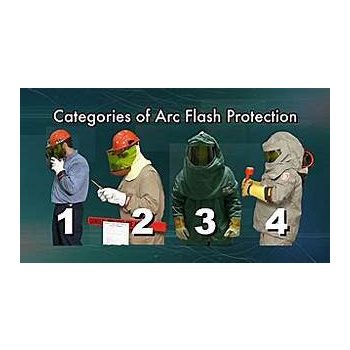

PPE Category signage and instruction

There should be clear signage at the entrance of all Switch-Rooms and Sub-Stations detailing PPE category and minimum PPE requirements for entry into the building.

It is an offence under the Electricity at Works Act, (EWA) to not provide safe working conditions, this is what H&S will scrutinise when making an investigative report on an Arc Flash incident. If no clear signage AND enforced instructions not clear and obvious via the company, the responsible person is liable to criminal prosecution, possible job loss and in extreme circumstances, (serious or fatal injury) unlimited fine and up to 2 years imprisonment. (If it is any consolation, the company owner(s) or Director(s) will not fare much better for being either ignorant of the law or allowing the law to be disregarded by one of their employees).

SLD of electrical distribution

This should be updated and given a new revision number for each change to the system. Once up to date, a copy clearly displayed within building, ideally on an internal wall adjacent to control and switchgear.

Correct protection settings and demarcation

Incorrect demarcation of devices or over-tolerant settings are common place, particular on older systems where additions or removals have not been considered and protection setting re-examined ad set to take this into consideration. Call or complete enquiry form for further advice.

Rusted switchgear

Switchgear with rust or paint chipped away may be an invite to moisture ingress.

Earth rubberised matting

Each switchgear and control panel should have rubberised insulation strip flooring, (in good condition) or it could become a trip hazard). This, (along with correct safety boots/shoes) particularly if exposed to live cables at any time, can be the difference between survival or fatality.

Internal moisture

Internal moisture can be commonplace, particular when wide ranging ambient and external temperatures prevail.

Rodent activity

Rodents/wild animals/snakes make wonderful conductors and a frequent reason for Arc Flash incidents. If they can find a way in they will and the warmest place once in….is the switchpanel.

New to site

‘Never switch without knowledge’ should be every LV & HV engineers personal method statement. Experience and knowledge on any site is invaluable to good safety isolations. Many installations have alterations that resident engineers are aware of, but not always identifiable. If there is no experience or if informational is not substantiated, it is essential an investigative study/survey is undertaken. We can advise further if requested; Call or complete enquiry form. In particular, beware remote isolations being a safety flag, they are only safe if the correct isolation breaker has taken place. CONFIRM DEAD…. PROVE DEAD! Ensure appropriate TAG & LOCK facilities and register are in place

No recent switching/isolation history

It may be that no switching has taken place previously, or it may be that correct safe switching methods have not been enforced.

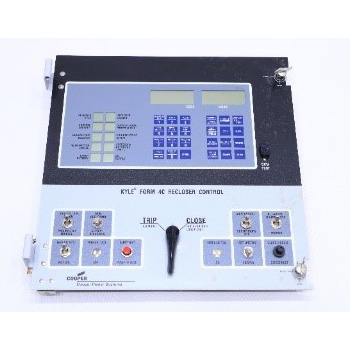

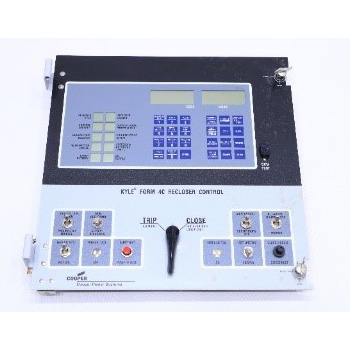

Remote Switching

We have examined all types and can advise, one of the most user friendly, low cost and easy retro fit systems has just been launched, watch this space for more news imminently.

Providers published on this site are experts in this field and can provide the exact requirements and any advice and guidelines.

Please either deal direct, (company details coming soon) or if you wish us to oversee at no additional cost to any project, either email either email david.davenport@transmaguk.co.uk or fill out our website enquiry form here.

10 TYPICAL OVERLOOKED SITUATIONS

No Distribution SLD on display

Alarm bells should ring if this is the situation. Recommend an investigative study/survey, contact, call or complete enquiry form us for more information, options and advice

Energy levels signage not displayed and therefor correct PPE category not identified

Unless you have a recognised Arc Flash monitoring and detection system in place, ( the type and manufacturer of the system will be able to state energy levels with the type and speed of triggering/isolation system). If no AF system, the only way to identify correct category is with an energy study, this is non-intrusive and easily carried out, contact, call or complete enquiry form for further information and advice

Planned outages without planned recovery in the event of issue arising

Even the best organised and planned outages can come across unexpected issues and the need to re-instate urgently. This should be part of the pre-planning that can take into account any stage of the isolation and working period and re-instatement of supply(s) We are always available for advice and guidance; Call or complete enquiry form.

Mistakenly identifying flame retardant as Arc Flash protection PPE

Amazing misconception is that flame resistant is actually sufficient as ARC Flash rated PPE….it is not! Injury during attendance with inadequate PPE will impact on the severity, any compensation for the engineer, (if survives) and his family. It will end up with H&S prosecution of responsible person(s), unlike any other court proceedings, in H&S prosecutions the accused are guilty and it is for the accused to PROVE their innocence, (ignorance is an automatic guilty verdict). Sentences will incorporate an, (unlimited) penalty fine and up to 2 years imprisonment. The fine will be personal and can enforce home sale in order to pay and can also result in a considerable company penalty fine if their procedures are at fault.

No Switching Statement, (or Switching Statement not signed off by Authorising Engineer)

All switching, planned isolations and works should be carried out by either an HV SAP:- (systems over 1kV) or an LV SAP, (Senior Authorised Person) or an LV AP (Authorised Person) :- (systems under 1kV).

No AP/SAP will switch and isolate without a Switching Statement, (unless in an emergency or crisis situation). Otherwise, they are not an AP/SAP.

Every Switching Statement should include isolation procedure and re-introduction procedure and a contingency procedure for recovery, probably drawn up by an Authorised Engineer, but at the very least signed off by an Authorising Engineer who will then nominate the AP/SAP and Safety Person.

Many companies overlook this procedure thus leaving the facilitating company and the responsible person(s) wide open for prosecution in the event of a mis-hap, possible huge fine(s) and imprisonment.

That is the mark of the importance of this procedure. If your on-site engineers carry out works such as this, send them on the appropriate course(s). If you use a sub-contractor service, ask for copy of certificates and file them with job documentation and ensure issue of a Works Permit, which the AP/SAP must sign prior to works and again sign-off upon safe completion of works. contact us, call or complete enquiry form for more advice/information

Pre-outage day walkthrough/simulation of switching via SAP and Safety person

It always provides additional good housekeeping and confidence to have a rehearsal walk through, stating out loud as to exactly what you will be switching whilst stationed in front of each appropriate switch. (with a respondent confirming aloud at each stage or segment of switching rehearsal) Running the isolation through your mind, thinking through what effect each switching will have on other devices. It will also give you an oversight for a risk assessment and any pending or imminent concerns. Call or complete enquiry form for further information or advice.

No Safety person present

Any SAP and/or Authorised Engineer will insist on the presence of an independent Safety Person, (throughout the isolation, works and re-introduction). The Safety Person should be aware of responsibility for clear access and exit without obstacle and obstruction, working environment uncluttered and safe to work in without inhibition, appropriate PPE and safety surroundings such as Rubber Matting. Also responsible for making sure no unauthorised access occurs at any time during procedures or works, clear danger and no access signage should be clearly displayed at each access point along with any hazard taping off of the restricted area.. The Safety Person is responsible for restricting unauthorised encroachment or visit. Call or complete enquiry form for more information or advice.

Prove dead AND confirm dead by SAP

A vital part of any switching statement, proving dead and then in front of all attendees confirming dead upon isolation and earthed down and locked and tagged out.

Inadequate Tag/lock out system, register and equipment

There are many good, safe systems, all engineers should use as second nature for any and all works involving switching/isolating. Call or complete enquiry form with any questions and we can advise.

Energy Audits

Energy Auditors arranged and organised with simplicity by providers that sponsor our site, the experts in this field and can provide the exact requirements and any advice and guidelines.

We can oversee at no additional cost to project or budget, either email david.davenport@transmaguk.co.uk or fill out our website enquiry form here.

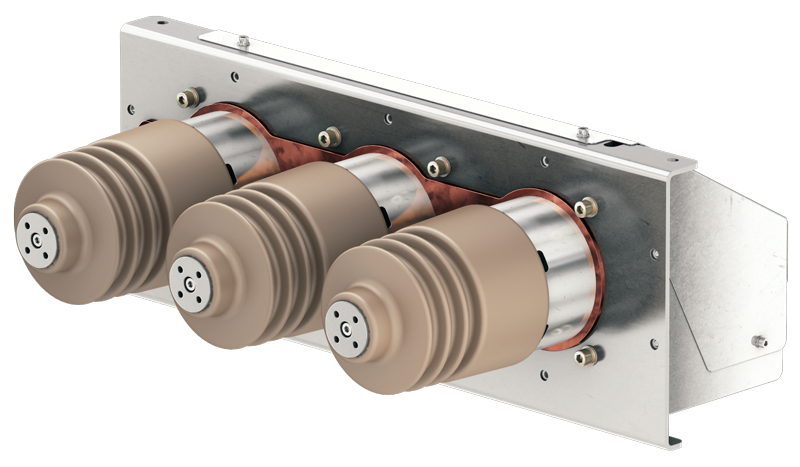

FORM 4 SWITCHGEAR & PANELS

Switchgear and panel builders that sponsor our site are experts in this field and can provide the exact requirements and any advice and guidelines.

Please either deal direct, or if you wish us to oversee at no additional cost to project or budget, either email either email david.davenport@transmaguk.co.uk or fill out our website enquiry form here.

RETRO FIT ARC FLASH PROTECTION

Retrofit panels, that are simplicity itself to install, minimal down time, we can also provide free consultation and bespoke design for your specific system and to your budget.

CPAS and/or Transmag are able to either train Electrical Engineers to install, commission and test or offer installation and commissioning and training.

With a 2ms AF trip signal, this is possibly the simplest and most effective way to, substantially increase safety and resilience of site as well as automatically reducing AF PPE requirements to category 2 or even category 1.

Transmag are experts in this field and can provide the exact requirements and any advice and guidelines. Please either deal direct, david.davenport@transmaguk.co.uk or fill out our website enquiry form here.

SERVICES

We provide a comprehensive range of services to our

customers through our own skilled staff and a global network

of partners.

ARCTEQ

ARC FLASH RELAYS & QUENCHERS

Siemens and Arcteq have a joint venture which brings you the most technically advanced and safe systems available on the market.

The full range is ONLY available in the UK via this website. Experts in this field, we can provide the exact requirements and any advice and guidelines.

All information is available via this link www.arcteq.fi OR

Contact us here at CPAS and we can offer:

- Free advice and guidance

- Arcteq product supply

- Site visits for

- Arc Flash Introduction, (non-commercial)

- Arc Flash H&S advice, (non-commercial)

- Proposal discussions on options and costs of options

- Product identification and specifications best suited for your site(s)

- Non-committal AF design to your dedicated system(s)

- Training

- Introductory

- Intermediatory

- Installation, Commissioning & Testing

- Advanced, (software programming)

- Installation

- Commissioning

- Testing & Servicing

email david.davenport@transmaguk.co.uk or fill out our website enquiry form here.

REFERENCES

5 key considerations when choosing a technology partner

5 key considerations when choosing a technology partner When shopping for a comprehensive SAAS (Software as a Service), ERP (Enterprise Resource Programme), or MRP (Materials Resource Planning )software solution, one must spend considerable amounts of time...

Great week for UK aerospace sector with return of Farnborough Airshow and host of positive news stories

Its been a great week for the UK’s aerospace sector with the return of the internationally renowned Farnborough Airshow and a host of positive news stories, including:: Boeing and the UK government announced plans to extend their successful long-term partnership,...

PTC launches new Windchill+ offering to help global customers accelerate SaaS journey

PTC (NASDAQ: PTC), which operates in the UK from its base in Farnborough, has today launched its Windchill+ product lifecycle management (PLM) software. Viewed by many as the next generation of the company’s market-leading Windchill® software, the new solution is...